Have questions?

We pride ourselves in delivering exceptional service with emphasis on safety, quality, and performance on every project.

Let us know how we can help.

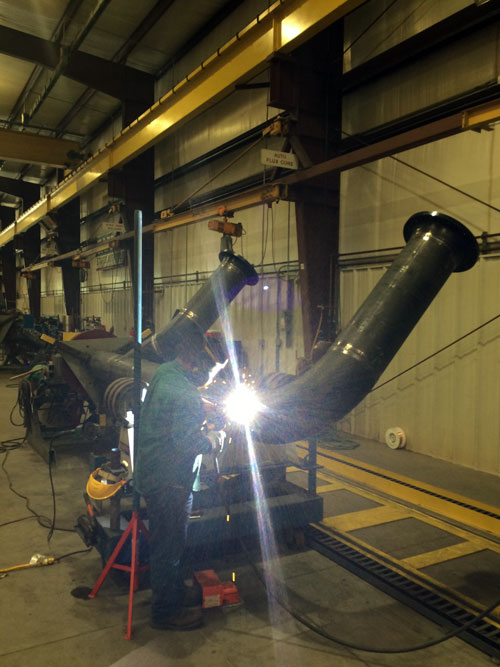

Pipe Fabrication

Our pipe fabrication operations utilize CNC automated and semi-automated equipment that produce high quality welds in minimal time.

Shop standards meet or exceed ASME B31.1, B31.3 and customer specific specifications. All welding is per ASME Section IX.

- ASME stamps: A, S, U, and PP

- National Board stamps: R and NB

- Qualified welding procedures: GMAW, GMAW-S, GTAW, SMAW, SAW, and FCAW

Preprogrammed cuts include straight cuts with bevels, saddles, miters and multiple interactions, centerline offsets, elbow supports and mid-section gusset slots, and multiple circular and rectangular holes.

- CNC pipe cutting and material handling equipment

- Root pass stations

- Automatic submerged arc welding

- Automatic FCAW welding

- Orbital welding

Vernon CNC Pipe Cutting and Material Handling Equipment

- 4 Axis Cutting Head

(3 in. through 48 in. pipe diameter capacity with maximum load of 30,000 lbs.) - 40 ft. Entrance Conveyor

(Hydraulic selector gates and variable speed, reversible power feed) - 40 ft. Discharge Conveyor

(Hydraulic selector gates and variable speed, reversible power feed) - 2 Torch, Straight Cut-Off assembly

(for cutting heavy wall pipe, 2 in. wall thickness and above and 200 Amp) - Plasma Cutting Unit

(up to 2 in. wall thickness) - WINIMPM-DT-Software Program

(for creating, editing, storing and displaying all cut variables)

Root Pass Station

- 3000# Welding Positioner

(Rotate pipe diameters from 3 in. to 45 in.) - 1 Ton Wall Mounted Jib Cranes

(1 ton lifting capacity) - 400 Amp Miller Pipeworx

(Welding capabilities: GTAW, FCAW, SMAW, GMAW, GMAW-S (RMD))

Automatic Submerged Arc Welder

- 4000# Welding Positioner

(Rotate pipe diameters from 3 in. to 50 in.) - 3000# Welding Positioner

(Rotate pipe diameters from 3 in. to 45 in.) - Pipe Turning Rolls

(Rotate pipe diameters from 3 in. to 60 in.) - Lincoln Sub-Arc Welding System

(NA 5 Control, Lincoln 600 amp power source) - 8 ft. x 8 ft. Welding Manipulator

(Variable speed control, 50 ft. travel distance) - 1 Ton Wall Mounted Jib Cranes

(1 ton lifting capacity) - 400 Amp Miller Pipeworx

(Welding capabilities: Tig, Stick, Flux Core and RMD Root)

Pipe Fabrication Expertise

For your next Construction project, give us a call at 1-877-339-2737 or drop us a line.